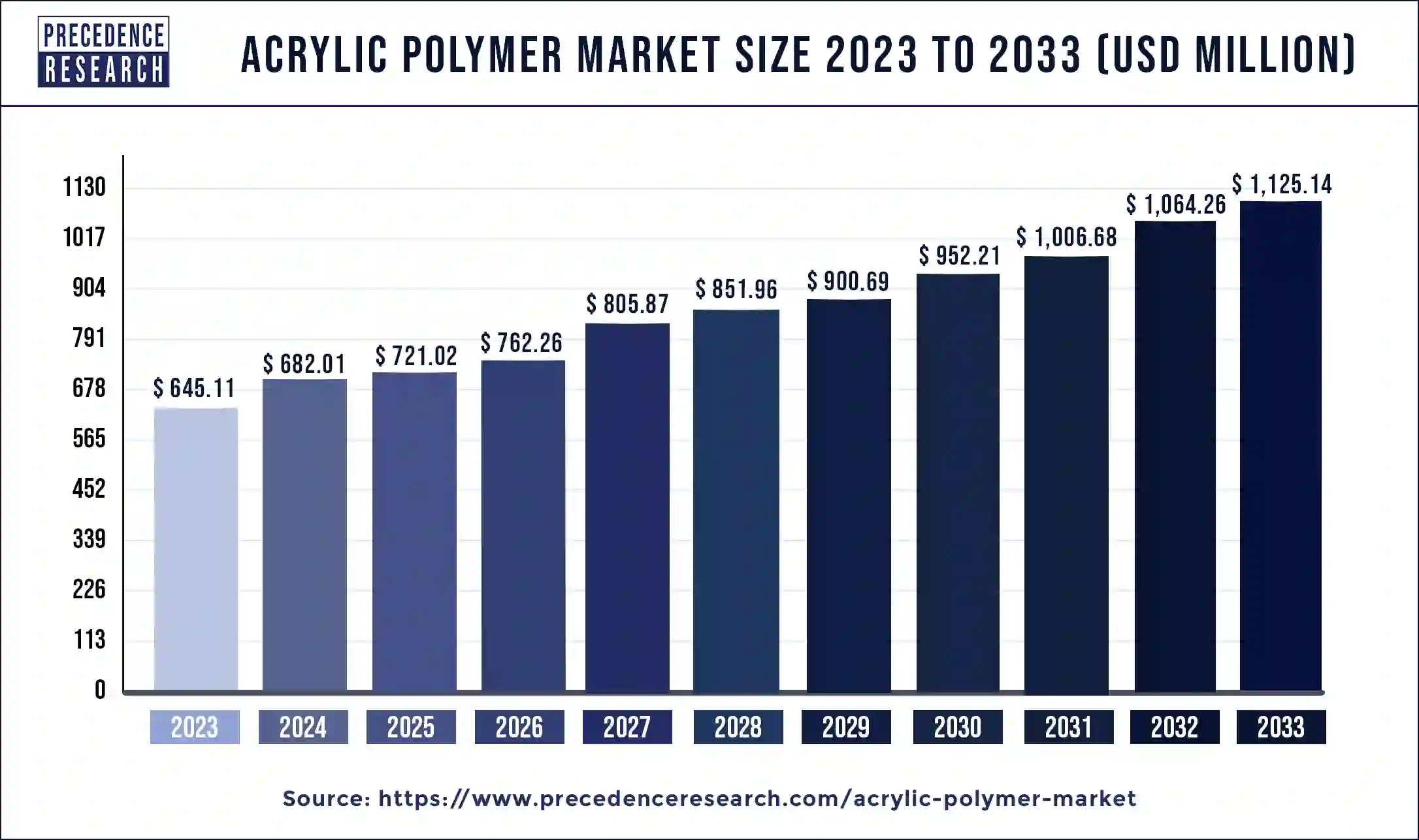

The global acrylic polymer market size surpassed USD 645.11 million in 2023 and is predicted to grow around USD 1,125.14 million by 2033, growing at a CAGR of 5.72% from 2024 to 2033.

Key Points

- North America dominated the market share in 2023.

- Asia-Pacific is estimated to expand at the fastest CAGR between 2024 and 2033.

- By type, the polymethyl methacrylate segment held the largest market share 22% in 2023.

- By type, the polyvinyl acetate segment is anticipated to grow at a remarkable CAGR between 2024 and 2033.

- By solution type, the water-borne segment generated the biggest market share 28% in 2023.

- By solution type, the solvent-borne segment is expected to expand at the fastest CAGR over the projected period.

- By application, the cosmetics segment has held a major market share of 31% in 2023.

- By application, the paints & coatings segment is expected to expand at the fastest CAGR over the projected period.

The acrylic polymer market is experiencing steady growth globally, driven by increasing demand across various end-use industries such as paints and coatings, adhesives and sealants, textiles, and construction. Acrylic polymers, derived from acrylic acid or its derivatives, offer versatile properties including durability, weather resistance, adhesion, and flexibility, making them ideal for a wide range of applications. With expanding industrialization, urbanization, and infrastructure development activities worldwide, the acrylic polymer market is poised for continuous expansion in the foreseeable future.

Get a Sample: https://www.precedenceresearch.com/sample/3978

Growth Factors:

Several factors contribute to the growth of the acrylic polymer market. One key driver is the growing demand for acrylic-based paints and coatings in the construction, automotive, and industrial sectors. Acrylic polymers provide excellent color retention, weatherability, and resistance to UV radiation, chemicals, and abrasion, making them preferred choices for protective and decorative coatings. Moreover, increasing awareness regarding environmental sustainability and regulations promoting low-VOC (volatile organic compound) formulations drive the adoption of water-based acrylic coatings, further fueling market growth.

Additionally, the expanding construction and infrastructure development activities worldwide stimulate demand for acrylic-based adhesives and sealants. Acrylic polymers offer superior bonding strength, flexibility, and durability, making them essential components in various construction applications such as caulks, sealants, and structural adhesives. Furthermore, the automotive industry’s shift towards lightweight materials and high-performance coatings drives the demand for acrylic-based automotive coatings, contributing to market expansion.

Moreover, technological advancements in acrylic polymer manufacturing processes, such as emulsion polymerization and solution polymerization, enhance production efficiency, product quality, and cost-effectiveness. Improved resin formulations, additives, and crosslinking agents enable the development of innovative acrylic polymer products tailored to specific end-use requirements, thereby widening application possibilities and market penetration.

Region Insights:

The acrylic polymer market exhibits a global presence, with key regions including North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. North America and Europe dominate the market owing to established industrial infrastructure, stringent environmental regulations, and a mature coatings and adhesives industry. The presence of prominent market players, research institutions, and technological expertise further strengthens the regions’ position in the acrylic polymer market.

In Asia-Pacific, rapid industrialization, urbanization, and infrastructure development activities drive market growth. Emerging economies such as China, India, and Southeast Asian countries witness robust demand for acrylic polymers in construction, automotive, and consumer goods sectors. Moreover, favorable government initiatives, foreign investments, and expanding manufacturing capabilities bolster market expansion across the region.

Latin America and the Middle East and Africa regions offer untapped growth opportunities for the acrylic polymer market. Rising construction spending, urbanization rates, and investments in infrastructure projects stimulate demand for acrylic-based coatings, adhesives, and sealants. Moreover, increasing automotive production and supportive government policies drive market growth in these regions, positioning them as promising markets for acrylic polymer manufacturers.

Acrylic Polymer Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 5.72% |

| Global Market Size in 2023 | USD 645.11 Million |

| Global Market Size by 2033 | USD 1,125.14 Million |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Type, By Solution Type, and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Acrylic Polymer Market Dynamics

Drivers:

Several factors drive the demand for acrylic polymers in various end-use industries. One significant driver is the rapid urbanization and infrastructural development, particularly in emerging economies. The construction of residential, commercial, and industrial infrastructure necessitates high-performance coatings, sealants, and adhesives for protection and aesthetic enhancement, thereby driving the demand for acrylic polymer-based products.

Additionally, the automotive industry’s continuous innovation and technological advancements propel the demand for acrylic-based coatings and polymers. Acrylic polymers offer lightweight, corrosion-resistant, and durable solutions for automotive coatings, contributing to fuel efficiency, vehicle aesthetics, and longevity. Moreover, stringent environmental regulations promoting low-VOC and eco-friendly coatings drive the adoption of water-based acrylic formulations in the automotive sector.

Furthermore, the increasing popularity of acrylic-based textiles and fibers in the fashion and apparel industry drives market growth. Acrylic fibers offer softness, warmth, and colorfastness, making them suitable for a wide range of apparel and textile applications. Moreover, acrylic polymers’ versatility enables the development of innovative textile blends and finishes, catering to evolving consumer preferences and fashion trends.

Opportunities:

The acrylic polymer market presents numerous opportunities for innovation and expansion. One significant opportunity lies in the development of bio-based and sustainable acrylic polymers derived from renewable feedstocks such as biomass, plant oils, and recycled materials. With growing emphasis on environmental sustainability and circular economy principles, bio-based acrylic polymers offer potential advantages in reducing carbon footprint, resource dependency, and environmental impact.

Moreover, technological advancements in acrylic polymer synthesis, formulation, and application techniques open avenues for product differentiation and market diversification. Innovations such as self-healing coatings, smart polymers, and functional additives enhance acrylic polymer performance and functionality, addressing evolving customer needs and industry requirements. Furthermore, collaborative research initiatives and strategic partnerships between industry players, research institutions, and government agencies foster innovation and accelerate the commercialization of advanced acrylic polymer technologies.

Additionally, expanding market penetration in emerging applications such as medical devices, electronics, and packaging presents growth opportunities for acrylic polymer manufacturers. Acrylic-based materials offer favorable properties such as biocompatibility, transparency, and chemical resistance, making them suitable for diverse medical, electronic, and packaging applications. Moreover, customization capabilities and tailor-made solutions enable acrylic polymer suppliers to address specific performance requirements and regulatory standards in these high-growth sectors.

Challenges:

Despite the favorable growth prospects, the acrylic polymer market faces several challenges that may impact its trajectory. One such challenge is the volatility of raw material prices and supply chain disruptions, particularly for petrochemical-derived acrylic monomers. Fluctuations in crude oil prices, geopolitical tensions, and trade uncertainties may affect acrylic polymer production costs and profitability, posing challenges for market players in managing input costs and pricing strategies.

Furthermore, environmental and regulatory concerns surrounding the use of certain acrylic polymers and additives, such as styrene-containing polymers and plasticizers, present challenges for market compliance and sustainability. Regulatory restrictions on hazardous substances, VOC emissions, and waste disposal necessitate continuous innovation in acrylic polymer formulations and manufacturing processes to meet evolving regulatory requirements and consumer preferences.

Moreover, competitive pressures and market consolidation pose challenges for small and medium-sized acrylic polymer manufacturers in maintaining market share and profitability. Intense competition from large multinational corporations, price competition, and shifting customer preferences for sustainable and high-performance solutions require agile business strategies and differentiation efforts to remain competitive in the market.

Read Also: Bispecific Antibodies Market Size, Share, Report by 2033

Recent Developments

- On February 9, 2023, Roehm, a chemical company based in Germany, unveiled two acrylic-based copolymer compounds, Cyrolite GP-20 and MD zk6, during the 2023 MD&M West trade show. Designed for injection molding and extrusion processes, these compounds demonstrated an outstanding combination of properties ideal for medical device applications.

Acrylic Polymer Market Companies

- BASF SE

- Dow Chemical Company

- Arkema SA

- Mitsubishi Chemical Corporation

- Evonik Industries AG

- Sumitomo Chemical Co., Ltd.

- LG Chem Ltd.

- Solvay SA

- Formosa Plastics Corporation

- Kuraray Co., Ltd.

- Nippon Shokubai Co., Ltd.

- DIC Corporation

- Celanese Corporation

- Mitsui Chemicals, Inc.

- Saudi Basic Industries Corporation (SABIC)

Segments Covered in the Report

By Type

- Polymethyl Methacrylate

- Sodium Polyacrylate

- Polyvinyl Acetate

- Polyacrylamide

- Others

By Solution Type

- Water-Borne

- Solvent-Borne

By Application

- Dentistry

- Cosmetics

- Paints & Coatings

- Cleaning

- Others

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/